Understanding curb colour

Shortcut: use the abbreviated Curb Picker photos to simplify the ordering process. or the full curb picker here

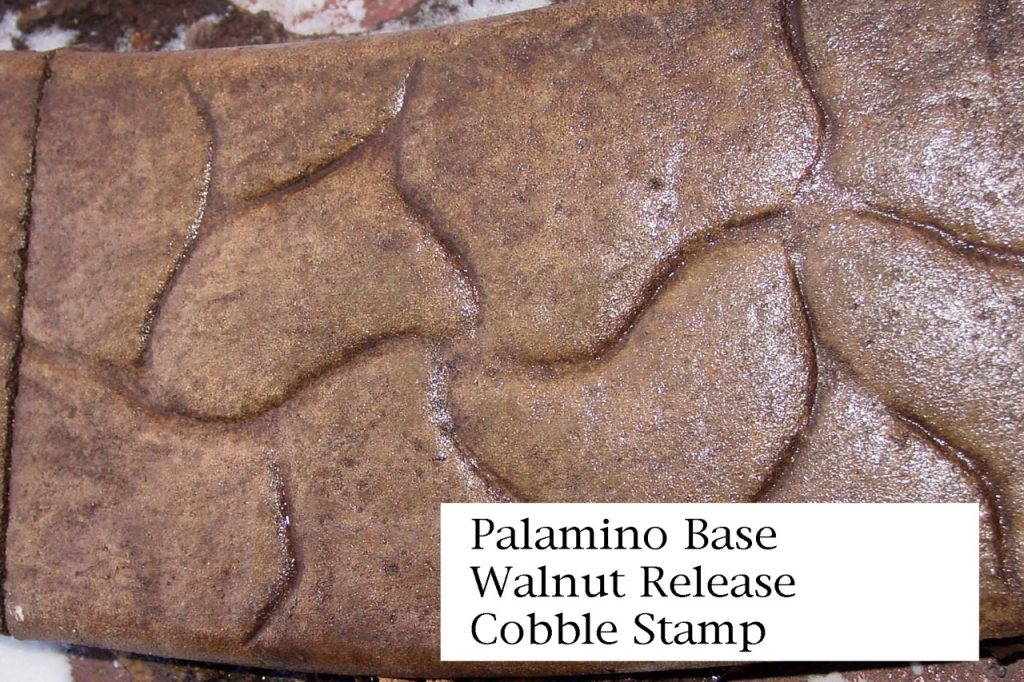

There are two kinds of colour involved with curbing.

1) The BASE colour also called Integral colour which is the colour the concrete is tinted throughout; and

2) The colours used in stamping which are called RELEASE colours because they prevent the texture stamp/s from sticking, and add coloured impressions, marks, and staining effects to the surface of the concrete.

Some curb companies use an untinted base colour of concrete and colour only the top layer using a slurry coating of “colour hardener” or their own mix. We do not use slurry colours. Their method saves a lot on integral colour, as the dyes are expensive. But when this inevitably chips, it shows a garish white scar that is almost impossible to repair or avoid seeing.

For that reason, we use integral colours only. We cannot achieve really strong colour contrasts the way slurry coating can, but for our climate, integral colours perform better and are much more durable. Also we have seen many slurry coats fail when applied in hot weather. Our system is similar to what is used around Edmonton on stamped sidewalks and driveways. You never see slurry coats used on a sidewalk because it does not last in our climate. Slurry coated curbing also tends to be much more expensive, as in the franchise system brands.

It is important to know that concrete colour is somewhat unpredictable due to many factors, and we do not have the same control over colour that people have grown to expect with paints. Variables include dye batches, cement colour, aggregate colour, heat, wind, humidity, technique and tools. If you doubt our word on it, just read the small print on the Davis colour brochure! Or go look at the tinted traffic barriers along the LRT in the Southgate area. The variations are enormous- yet the concrete was done by the most experienced contractors in the city, and supplied by computerized batch systems.

Colour charts are also somewhat unreliable, particularly as viewed on a computer screen. Charts are just an approximate guide are to the final outcome. Concrete dyes are generally made using oxides of iron and copper. This causes them to tend toward “pink” when using some browns especially. Perfect colour matches when adding on or repairing concrete are very difficult or impossible to achieve.

When specifying colour combinations, please use the nomenclature attached to the photos in our “curb picker” gallery, ie. the terminology used on our website. If you have something in mind that you don’t see, please don’t hesitate to ask.

1) Concrete Integral (base) colours:

You will notice in the chart below there are colours named by our supplier- Davis Colours , right on each chip. WE DO NOT USE THEIR NOMENCLATURE, just their numbers! Please use the name below each chip when communicating with us. We use the colour number or main name with variations of LIGHT, MEDIUM, and DARK sometimes VERY DARK. This system avoids errors in the field. So when you specify a colour for us you use the term UNDER the chip please. The curb picker has the colours named as we use them

Here is the base colour palette: colours can be lightened but not darkened from this approximate tone.

2) Release Colours:

We use Brickform release colours. Not all colours manufactured by Brickform are available to us, nor are they all useful in curbing, so we are picturing the ones we commonly use.

See the release colour palette below: